baginbox-packaging

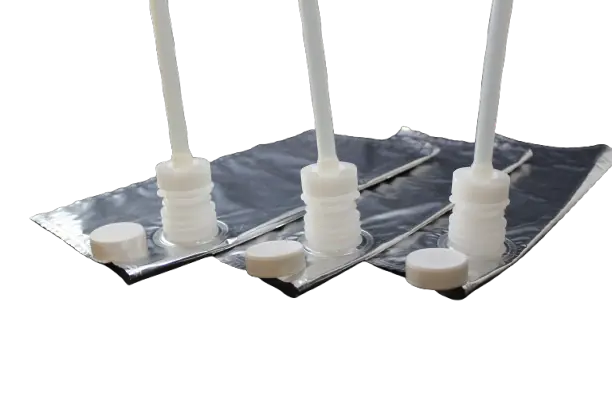

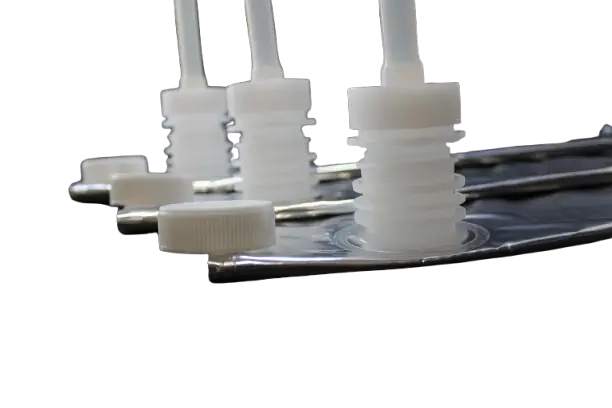

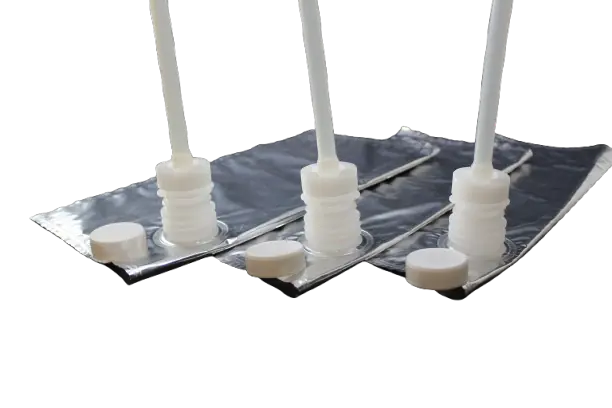

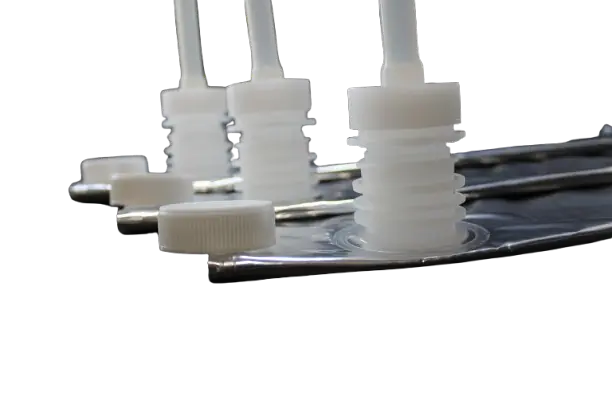

FDpack® High Barrier Aseptic Bag-in-Box (BIB) Packaging | 1L-25L with 393/700/2000 Tube Caps & 1" Pipe | VMPET, EVOH, PE, PA, PET, ALU Materials

FDpack® High Barrier Aseptic Bag-in-Box (BIB) Packaging | 1L-25L with 393/700/2000 Tube Caps & 1" Pipe | VMPET, EVOH, PE, PA, PET, ALU Materials

Couldn't load pickup availability

Product Description

FDpack® Professional Bag-in-Box (BIB) Solutions Dispensing tubes for tea urn-liners as well as tubes for use in bag-in-box dairy,Beverages, Syrups & Liquid coffee and juice commercial dispensing machines, with irradiatable options available.

Elevate your liquid packaging with FDpack’s high-barrier, aseptic Bag-in-Box (BIB) systems, designed for durability, hygiene, and cost-efficiency. Ideal for commercial and consumer applications, our BIB packaging is trusted for soda, cola, juice, syrup, dairy, coffee, and even boxed wine.

Key Features:

✅ Multi-Layer Barrier Materials:

VMPET | EVOH | PE | PA | PET | ALU

Choose from Standard, High, or Ultra-High Barrier films to protect against oxygen, moisture, and contaminants.

✅ Versatile Sizes & Compatibility:

Bag Volumes:1L,3L, 5L, 10L, 20L, 25L

Tube Caps & Adapters: 393 Tube Cap, 700 Tube Cap, 2000 Tube Cap, 1" Pipe

Irradiatable Options: Sterilized via ≥15kGy irradiation for extended shelf life.

✅ Aseptic & Sanitary Design:

Solvent-free lamination ensures food safety.

Integrated one-way valve prevents contamination, perfect for fast-food syrup dispensers, beverage fountains, and dairy/coffee machines.

✅ Durable & Flexible:

Top Flex Crack-Resistant film withstands rigorous handling.

Compliant with ABMA European Standards for quality assurance.

Applications:

Commercial: Soft drink syrups, tea urn liners, dairy dispensing, condiments.

Consumer: Boxed wine, bulk juice, eco-friendly liquid storage.

Trust FDpack for FDA-compliant, sustainable BIB solutions that reduce waste and optimize dispensing efficiency.

Share

Industry News |Bag-in-Box Packaging Manufacturer | Custom Solutions for Juice, Wine, Dairy, Chemicals & More

-

Vitop Bag-in-Box Tap: The Global Standard for F...

Discover the Vitop Tap—the world's leading Bag-in-Box dispensing solution. Engineered for superior product protection, extended shelf life, and effortless operation across food, beverage, and industrial applications.

Vitop Bag-in-Box Tap: The Global Standard for F...

Discover the Vitop Tap—the world's leading Bag-in-Box dispensing solution. Engineered for superior product protection, extended shelf life, and effortless operation across food, beverage, and industrial applications.

-

Bag in Box: The Ultimate Guide to Sustainable a...

Discover the benefits of Bag in Box packaging: a sustainable, cost-effective solution for wine, beverages, and more. Extend shelf life, reduce waste, and lower carbon footprint.

Bag in Box: The Ultimate Guide to Sustainable a...

Discover the benefits of Bag in Box packaging: a sustainable, cost-effective solution for wine, beverages, and more. Extend shelf life, reduce waste, and lower carbon footprint.

-

Bag-in-Box (BIB) & Stand Up Pouch (SUP) Fillin...

The FenDa Bag-in-Box (BIB) & Stand Up Pouch (SUP) Filling Machines are advanced, versatile solutions designed for precision filling of thick and viscous liquids into two popular flexible packaging formats:...

Bag-in-Box (BIB) & Stand Up Pouch (SUP) Fillin...

The FenDa Bag-in-Box (BIB) & Stand Up Pouch (SUP) Filling Machines are advanced, versatile solutions designed for precision filling of thick and viscous liquids into two popular flexible packaging formats:...

-

Bags in Box (BIB): 4 Sustainable Advantages for...

Discover why Aseptic Bag-in-Box (BIB) packaging outperforms traditional options. Reduce emissions by 52%, save space, and enhance freshness for juices, wine, milk, and oils. Explore 5L to 220L solutions.

Bags in Box (BIB): 4 Sustainable Advantages for...

Discover why Aseptic Bag-in-Box (BIB) packaging outperforms traditional options. Reduce emissions by 52%, save space, and enhance freshness for juices, wine, milk, and oils. Explore 5L to 220L solutions.

Contact form

Why Choose Bag-in-Box Packaging? Why Choose FDpack’s Bag-in-Box Solutions?

Discover why Bag-in-Box packaging is the future of liquid storage. Learn how FDpack’s FDA-compliant, eco-friendly solutions for dairy, wine, and liquid eggs outperform traditional packaging. Request free samples today!

Why Choose Bag-in-Box Packaging?

In today’s fast-paced, sustainability-driven market, Bag-in-Box (BiB) packaging has emerged as the go-to solution for liquid storage and dispensing. Here’s why:

Extended Shelf Life:

Multi-layer oxygen-barrier films (EVOH, aluminum) reduce oxygen permeability to <0.1 cc/m²/day, preserving freshness 2–3x longer than traditional packaging.

Ideal for dairy products (milk, yogurt), wine, and liquid eggs.

Sustainability & Cost Efficiency:

Lightweight design cuts shipping costs by 40% and reduces carbon footprint.

Recyclable materials align with global sustainability goals, minimizing waste.

Convenience & Versatility:

Ergonomic dispensing taps ensure easy pouring and 95% product evacuation.

Available in sizes from 1.5L to 20L, perfect for foodservice, institutions, and retail.

Hygienic & Safe:

Aseptic filling and tamper-evident seals ensure product safety from fill to final use.

Compliant with FDA, EU, and BRC Global Standards.

Why Choose FDpack’s Bag-in-Box Solutions?

At FDpack Technology, we go beyond standard BiB packaging to deliver innovative, customizable, and eco-friendly solutions tailored to your needs. Here’s what sets us apart:

Advanced Barrier Technology:

Our multi-layer films (EVOH, metallized PET, aluminum) offer superior protection against oxygen, light, and contamination.

Perfect for UHT milk, wine, and liquid eggs, ensuring extended shelf life even under transport stress.

Customization & Flexibility:

Tailored sizes (1.5L, 3L, 5L, 10L, 20L,220,1000L,1400L) and dispensing options (stainless steel taps, Vitop® seals) to match your brand and application.

MOQ-friendly production with rapid turnaround times (7–10 days for samples).

Proven Expertise:

Trusted by industry leaders like Yili Group, delivering 5M+ BiB units annually.

Rigorous QC testing: Every batch undergoes leak, burst, and seal integrity checks.

Sustainability Commitment:

Recyclable materials and energy-efficient production reduce environmental impact.

Carbon-neutral options available for eco-conscious brands.

Global Compliance & Support:

Compliant with FDA, EU, and ISO 22000 standards for food safety.

Door-to-door logistics and duty-paid options for seamless global delivery.

Applications of FDpack’s Bag-in-Box Solutions

Dairy: Milk, yogurt, cream, liquid cheese, and ice cream mix.

Beverages: Wine, spirits, pre-mixed cocktails, and fruit juices.

Liquid Eggs: Safe, hygienic packaging for foodservice and retail.

Industrial Liquids: Chemicals, lubricants, and specialty fluids.

Free Sample Offer

Experience the FDpack difference firsthand! Request free samples of our 5L BiB system and discover how our solutions can transform your liquid packaging.

Elevate your liquid packaging with FDpack’s cutting-edge BiB solutions—request a quote today!