baginbox-packaging

Bag-in-Box (BIB) & Stand Up Pouch (SUP) Filling Machines

Bag-in-Box (BIB) & Stand Up Pouch (SUP) Filling Machines

Couldn't load pickup availability

Key Features

Dual Packaging Compatibility

- Bag-in-Box (BIB): Optimized for large-volume packaging, ideal for cost-effective storage and transportation of products like purees, dairy, condiments, and industrial pastes. Pre-vacuuming technology ensures air-free packaging, extending shelf life.

- Stand Up Pouch (SUP): Designed for retail-ready, portable packaging. Supports 自立袋 (stand-up pouches) with spouts or zippers, suitable for snacks, beverages, personal care products, and more. Equipped with precise pouch positioning and sealing systems for secure, leak-free packaging.

Precision Weight-Based Filling

- Advanced Technology: Combines rotor pumps, high-accuracy weight sensors, and intelligent weighing modules to monitor filling in real time, ensuring consistent ±1% accuracy for both BIB and SUP formats.

- Stable Performance: Handles nectar-thick to honey-thick viscosities with equal precision, minimizing product waste and ensuring uniform quality.

High-Speed Efficiency

- BIB Capacity: Up to 360 bags/hour (water-based), maximizing large-scale production output.

- SUP Adaptability: Adjustable speeds to match pouch size and product viscosity, ensuring efficient throughput for retail-oriented packaging.

Fully Automated Operation

-

Seamless Process:

- BIB: Automatic bag locking, cap removal, pre-vacuuming, filling, and recapping.

- SUP: Pouch feeding, spout alignment, filling, and heat-sealing (or pressure-sealing for spouted pouches).

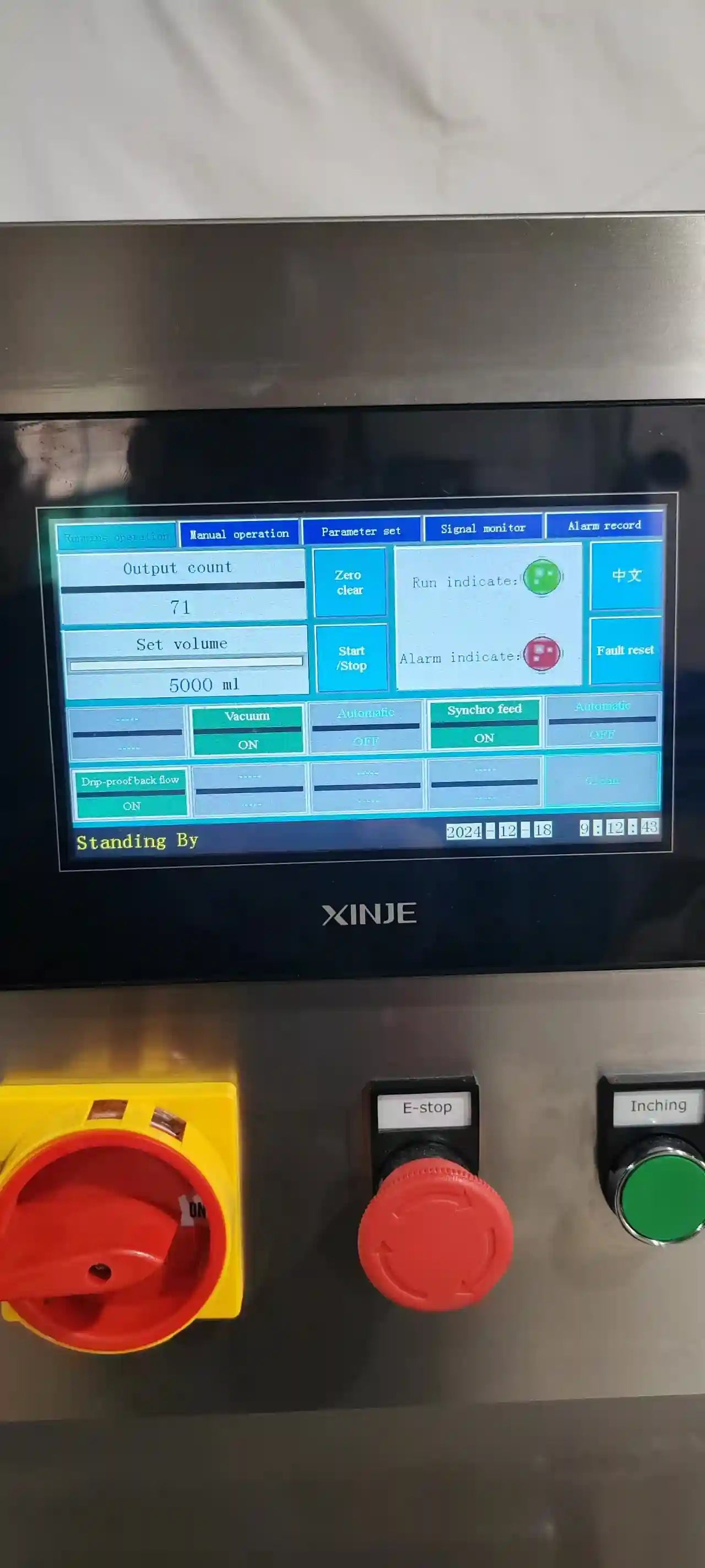

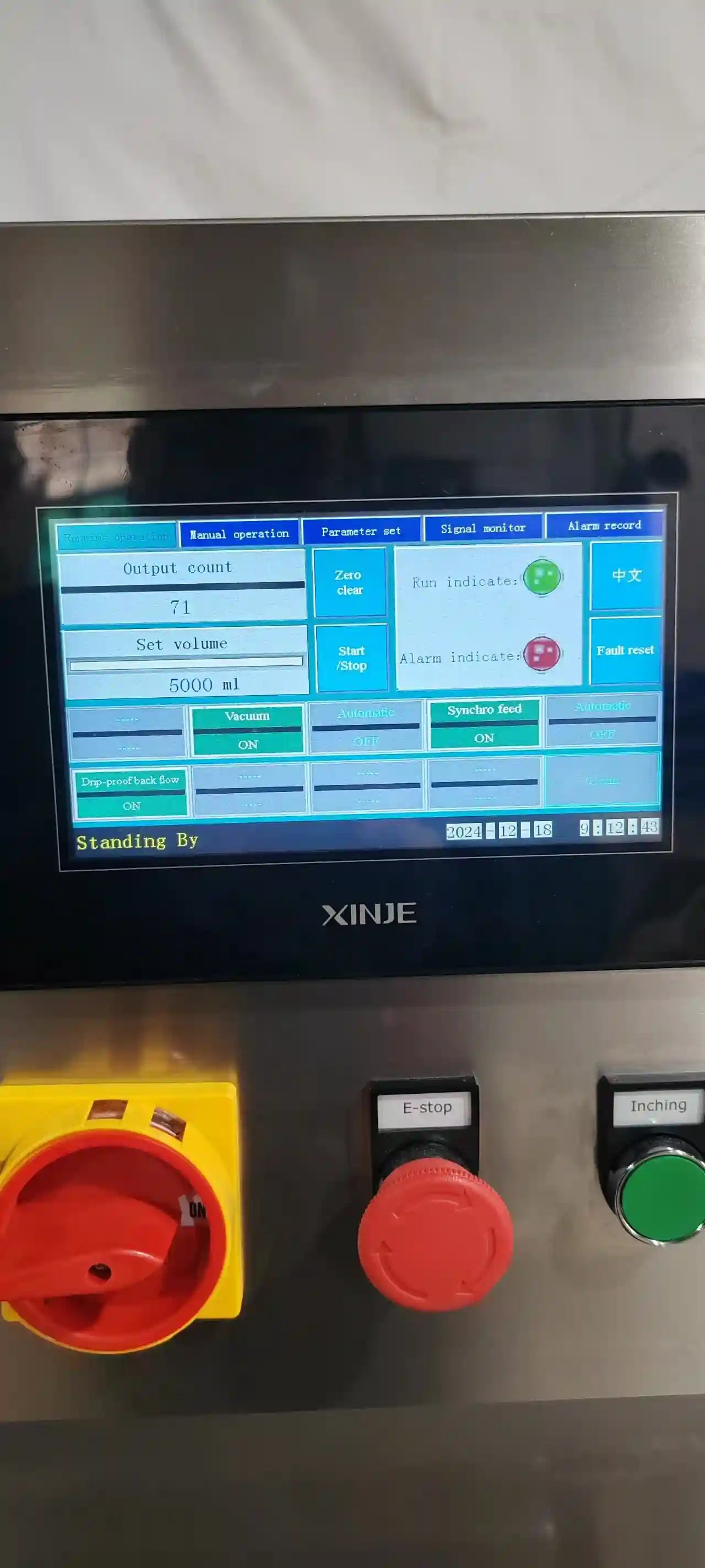

- User-Friendly: Simple HMI interface; operators only need to load packaging materials, set parameters, and start—no complex manual adjustments required.

Durable & Hygienic Design

- Premium Materials: Constructed with food-grade stainless steel and corrosion-resistant components to maintain product integrity and comply with global safety standards (FDA, CE).

- Easy Maintenance: Quick-release parts and smooth surfaces enable effortless cleaning, reducing downtime and ensuring hygienic operations.

Customizable Solutions

- Flexible Configurations: Available with single or double filling heads to match production demands.

- Tailored Options: Compatible with multiple pump types (rotor, piston) and additional modules (flowmeters, metal detectors) for specialized applications.

Technical Specifications

| Parameter | BIB Filling | SUP Filling |

|---|---|---|

| Filling Range | 1–30 kg | 0.1–5 kg |

| Filling Precision | ±1% | ±1% |

| Max Speed (Water-Based) | 360 bags/hour | 360 pouches/hour* |

| Material Viscosity | Nectar to honey-thick | Low to high viscosity |

| Operating Pressure | 0.5–0.6 MPa | 0.5–0.6 MPa |

| Supply Voltage | AC220V/50Hz ±10% | AC220V/50Hz ±10% |

| Air Consumption | ≥ 0.36 m³/min | ≥ 0.4 m³/min |

| Filling Temperature | ≤ 95°C | ≤ 80°C (heat-sealing safe) |

| Power per Head | 1.5 kW | 1.2 kW |

How It Works

Bag-in-Box (BIB) Process:

- Bag Insertion: Place empty BIB into the spout holder.

-

Automatic Cycle:

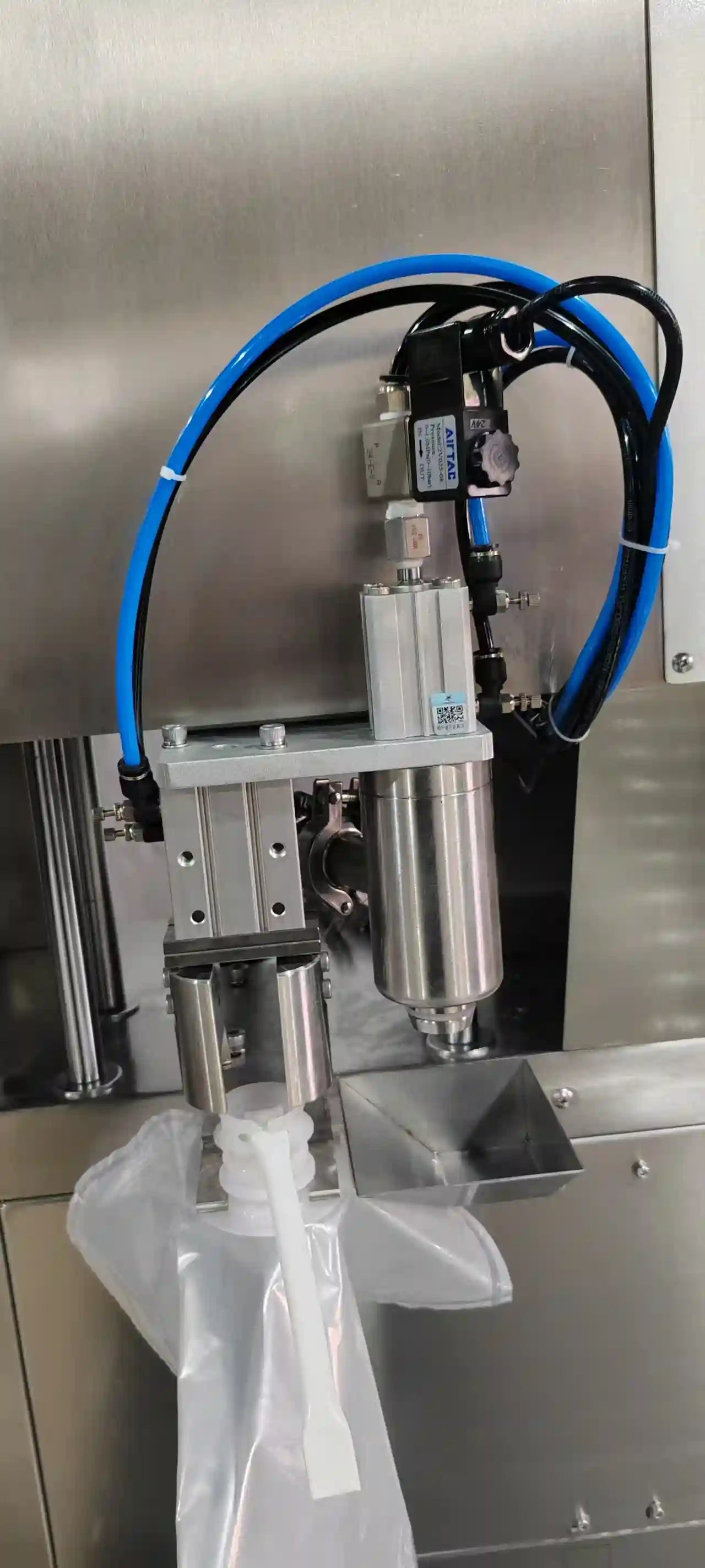

- Machine locks the bag, removes the cap, and inserts the product valve.

- Pre-vacuum removes residual air to prevent oxidation.

- Rotor pump dispenses product until the target weight (monitored by weight sensors) is reached.

- Sealing & Ejection: Bag is recapped, and the filled BIB is released for boxing.

Stand Up Pouch (SUP) Process:

- Pouch Loading: Position empty SUP on the conveyor or holder.

-

Automatic Cycle:

- Pouch is opened and aligned by mechanical grippers.

- Filling nozzle inserts into the pouch (or spout), and product is dispensed via weight-controlled pumping.

- After filling, the pouch is heat-sealed (or spout is capped) and ejected to the output conveyor.

Applications

Food Industry:

- BIB: Purees, ketchup, condensed milk, cheese sauce, mayonnaise, yogurt, liquid eggs, soft ice cream.

- SUP: Snack sauces, honey, nut butter, liquid seasonings, single-serve beverages, cooking oils.

Non-Food Industry:

- BIB: Industrial pastes, lubricants, chemicals, construction adhesives.

- SUP: Laundry detergents, shampoos, body lotions, automotive fluids, agricultural concentrates.

Why Choose FenDa Filling Machines?

- Cost Efficiency: Reduces packaging, storage, and logistics costs compared to rigid containers.

- Quality Assurance: Pre-vacuum (BIB) and air-tight sealing (SUP) protect product integrity and extend shelf life.

- Adaptability: Quick changeover between BIB and SUP formats with minimal downtime, ideal for multi-product lines.

- Reliability: Low maintenance, durable construction, and proven performance for 24/7 operations.

- Global Compliance: Meets strict hygiene and safety standards for food, pharmaceutical, and industrial applications.

Conclusion

Share

Industry News |Bag-in-Box Packaging Manufacturer | Custom Solutions for Juice, Wine, Dairy, Chemicals & More

-

Blog post

Give your customers a summary of your blog post

Blog post

Give your customers a summary of your blog post

-

Blog post

Give your customers a summary of your blog post

Blog post

Give your customers a summary of your blog post

-

Blog post

Give your customers a summary of your blog post

Blog post

Give your customers a summary of your blog post

-

Blog post

Give your customers a summary of your blog post

Blog post

Give your customers a summary of your blog post

Contact form

Why Choose Bag-in-Box Packaging? Why Choose FDpack’s Bag-in-Box Solutions?

Discover why Bag-in-Box packaging is the future of liquid storage. Learn how FDpack’s FDA-compliant, eco-friendly solutions for dairy, wine, and liquid eggs outperform traditional packaging. Request free samples today!

Why Choose Bag-in-Box Packaging?

In today’s fast-paced, sustainability-driven market, Bag-in-Box (BiB) packaging has emerged as the go-to solution for liquid storage and dispensing. Here’s why:

Extended Shelf Life:

Multi-layer oxygen-barrier films (EVOH, aluminum) reduce oxygen permeability to <0.1 cc/m²/day, preserving freshness 2–3x longer than traditional packaging.

Ideal for dairy products (milk, yogurt), wine, and liquid eggs.

Sustainability & Cost Efficiency:

Lightweight design cuts shipping costs by 40% and reduces carbon footprint.

Recyclable materials align with global sustainability goals, minimizing waste.

Convenience & Versatility:

Ergonomic dispensing taps ensure easy pouring and 95% product evacuation.

Available in sizes from 1.5L to 20L, perfect for foodservice, institutions, and retail.

Hygienic & Safe:

Aseptic filling and tamper-evident seals ensure product safety from fill to final use.

Compliant with FDA, EU, and BRC Global Standards.

Why Choose FDpack’s Bag-in-Box Solutions?

At FDpack Technology, we go beyond standard BiB packaging to deliver innovative, customizable, and eco-friendly solutions tailored to your needs. Here’s what sets us apart:

Advanced Barrier Technology:

Our multi-layer films (EVOH, metallized PET, aluminum) offer superior protection against oxygen, light, and contamination.

Perfect for UHT milk, wine, and liquid eggs, ensuring extended shelf life even under transport stress.

Customization & Flexibility:

Tailored sizes (1.5L, 3L, 5L, 10L, 20L,220,1000L,1400L) and dispensing options (stainless steel taps, Vitop® seals) to match your brand and application.

MOQ-friendly production with rapid turnaround times (7–10 days for samples).

Proven Expertise:

Trusted by industry leaders like Yili Group, delivering 5M+ BiB units annually.

Rigorous QC testing: Every batch undergoes leak, burst, and seal integrity checks.

Sustainability Commitment:

Recyclable materials and energy-efficient production reduce environmental impact.

Carbon-neutral options available for eco-conscious brands.

Global Compliance & Support:

Compliant with FDA, EU, and ISO 22000 standards for food safety.

Door-to-door logistics and duty-paid options for seamless global delivery.

Applications of FDpack’s Bag-in-Box Solutions

Dairy: Milk, yogurt, cream, liquid cheese, and ice cream mix.

Beverages: Wine, spirits, pre-mixed cocktails, and fruit juices.

Liquid Eggs: Safe, hygienic packaging for foodservice and retail.

Industrial Liquids: Chemicals, lubricants, and specialty fluids.

Free Sample Offer

Experience the FDpack difference firsthand! Request free samples of our 5L BiB system and discover how our solutions can transform your liquid packaging.

Elevate your liquid packaging with FDpack’s cutting-edge BiB solutions—request a quote today!